When buying lubricants, you have to consider how long they will last. For high-volume users, this is not as much of an issue compared to smaller-volume users. High-volume users’ regularly consumer and reorder lubricants and typically have systems in place to monitor usage and spending. Small-volume users might be spread a drum or two of a lubricant through the course of a year. When consumption is spread out, you have to start to consider shelf-life into your purchasing decisions and operational processes.

Where can I find Shelf-Life Information?

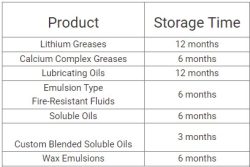

Information on a lubricant’s shelf life can be found on a technical or safety data sheet. If it is no t clearly defined, manufacturers and distributors can provide guidance on shelf life for its products. However, this information might be based on storage only or based on typical operations. George Wills and Dr. A.R. Landsdown provide a brief list of lubricants and their shelf-lives for products that have shorter shelf-lives.

Some technical data sheets (TDS) can show how long a lubricant can last in use before losing oxidation stability. This is measured in operating hours. Most oxidation tests will show a lubricant can last 5000+, 8000+, 10000+, etc. hours. However, like all scientific tests, this is done in a controlled environment (usually set by ISO or ASTM standards and specifications). We know that not every operating environment is like an ASTM or ISO test.

What Determines a Lubricant’s Shelf Life?

A lubricant’s shelf life depends on a variety of factors; some of which depend on the lubricant itself and some depend on usage. Greases have much shorter shelf life due to the presence of thickeners than oil-based lubricants. Highly-refined and synthetic oils have longer shelf lives due to better molecular stability. This is much more straight-forward and lubricant suppliers can inform you which lubricants last longer than others.

Using a lubricant is different for each operation. Some operations happen at low temperatures, others occur at high temperatures. The Arrhenius rate is a chemistry term that demonstrates how chemical reactions increase by changing temperature. For lubricants, as temperature increases by 10°C (18°F), the oxidation rate will double. The more oxidation that occurs, the faster a lubricant will break down and reduce the shelf life and effective use life.

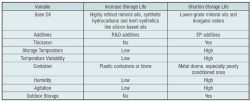

Machinery Lubrication compiled a chart from its experts to show what can increase or decrease a lubricants shelf life.

How can you Reduce Oxidation?

Oxidation occurs when the lubricant comes into contact with air. Certain lubricants are more susceptible to faster oxidation and degradation due to the composition of the lubricant. However, these are known and can be accounted for, whereas human factors are a much greater influence on degradation and chemical stability.

Storage is key to maintain longer shelf-life and higher lubricant performance. Some things that can improve shelf-life include:

- Storing lubricants in proper ambient temperatures. Cooler temperatures around 68°F are ideal.

- Storing lubricants in dryer environments. Ambient humidity and moisture increase oxidation and lubricant breakdown.

- Storing lubricants indoors. Outdoor storage can expose lubricants to more extreme and volatile conditions.

- Storing lubricants in proper containers. Poor-quality steel containers can expose the oil to iron and fuel oxidation. Plastic or plastic-lined drums are ideal for storage.

- Reduce agitation of the lubricant. The move the lubricant is agitated or moved, the more surface area of oil is exposed to air and can oxidize.

- Evaluate usage and purchase lubricants accordingly. This smooths out spending, but also reduces the likelihood of using older products.

- Practice First-In-First-Out (FIFO) when using lubricants. This prevents lubricants from sitting and aging.

- Label lubricants, containers, and machines. Knowing when a lubricant was made or put into use allows individuals to be more mindful of when to change lubricants.

How do I Get Informed?

Unfortunately, there is no industry consensus on shelf-life. Following the tips above will extend and maintain shelf-life. Speaking with manufacturers, distributors, and engineers is the best option in getting product-specific shelf-life information. Manufacturers will know exactly what goes into their products and can provide shelf-life information and best practices for storage.

Twin Specialties can provide information about Best Practices for Lubricant Storage and Managing Metalworking Fluids. We work with manufacturers to provide transparency and information about lubricant shelf-life and usage. Contact Twin Specialties for information about lubricants, best practices, and shelf-life.