Hydraulic oils are critical components of hydraulic systems, serving as the lubricant and coolant for hydraulic pumps, valves, cylinders, and other components. With a wide variety of hydraulic oils available on the market today, selecting the right hydraulic oil for a particular application is critical to ensure maximum performance, reliability, and longevity of hydraulic systems.

Types of Hydraulic Fluids

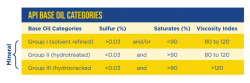

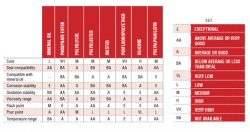

There are several types of hydraulic oils available on the market, including mineral oils, synthetic oils, and biodegradable oils. Mineral oils are the most common type of hydraulic oil, made from crude oil and refined through a distillation process. These oils are affordable, widely available, and have good lubrication properties. However, they have limited resistance to oxidation, which can lead to oil breakdown and sludge formation.

Synthetic oils are engineered oils that provide superior performance and durability compared to mineral oils. They are made from a variety of base stocks, including esters, polyglycols, and silicones, and are often blended with additives to improve lubricity, anti-wear properties, and resistance to oxidation. Synthetic oils are generally more expensive than mineral oils, but they offer better performance and longevity, making them ideal for high-pressure hydraulic systems and extreme temperature environments.

Biodegradable hydraulic oils are specially formulated to meet environmental regulations and minimize ecological impact. These oils are made from vegetable oils, esters, or other biodegradable base stocks, and are designed to break down quickly in the environment. Biodegradable oils are typically more expensive than mineral and synthetic oils, but they offer superior environmental performance and safety.

Water-glycol fluids are a mixture of water and glycol, and they are known for their excellent heat dissipation properties. They are commonly used in high-heat applications, such as in steel mills and other heavy-duty industrial applications. However, they are not as widely used as mineral, synthetic, or bio-based oils, and they are generally more expensive.

Factors for Selecting a Fluid

When selecting a hydraulic oil, it’s important to consider the specific requirements of the hydraulic system and the operating conditions. For example, hydraulic systems operating in cold environments may require a hydraulic oil with low pour point to ensure adequate fluidity and lubricity. Similarly, hydraulic systems operating in high-temperature environments may require a hydraulic oil with high thermal stability to prevent oxidation and viscosity breakdown.

Different hydraulic oils also have different viscosity grades, which determine the flow rate and resistance to flow of the oil. Viscosity grades are typically expressed in numbers, such as ISO 32 or ISO 46, with higher numbers indicating higher viscosity. The viscosity grade of the hydraulic oil should match the recommended grade specified in the equipment manufacturer’s manual.

In terms of cost and performance, mineral oils are the most affordable type of hydraulic oil, but they may require more frequent oil changes and maintenance due to their limited resistance to oxidation. Synthetic oils are more expensive, but they offer superior performance and longevity, making them ideal for high-pressure hydraulic systems and extreme temperature environments. Biodegradable oils are the most expensive, but they offer superior environmental performance and safety. The choice of oil will depend on the specific application and the user’s priorities.

Different hydraulic oil manufacturers may also have variations in their product formulations, additives, and performance characteristics. It’s important to choose a reputable manufacturer and ensure that the hydraulic oil meets the required specifications and performance standards for the specific application. Some of the most well-known manufacturers include Mobil, Shell, Chevron, and Castrol. These companies have a reputation for producing high-quality oils that are suitable for a wide range of applications. Other manufacturers may have a focus on a particular type of oil or a niche application.

Conclusion

In conclusion, selecting the right hydraulic oil for a particular application is critical to ensure maximum performance, reliability, and longevity of hydraulic systems. Mineral oils, synthetic oils, and biodegradable oils are the main types of hydraulic oils available on the market, each with their own advantages and disadvantages in terms of cost, performance, and environmental impact. When selecting a hydraulic oil, it’s important to consider the specific requirements of the hydraulic system and the operating conditions, as well as the viscosity grade and the reputation of the manufacturer. By choosing the right hydraulic oil, businesses can improve the efficiency and effectiveness of their hydraulic systems, minimize downtime and maintenance costs, and maximize the lifespan of their equipment.

Twin Specialties distributes a full line of hydraulic fluids and other industrial fluids to meet any and all manufacturing demands. Contact a Twin Specialties representative to learn more about our product lines and/or get a quote.