During the winter months and in cold weather regions, operators will face cold starts regularly and must select lubricants that ensure proper performance and protect your machine or engine. We will focus on key features that will differentiate lubricants that excel in cold weather and lubricants that will lead to machine or engine failure.

Viscosity

Not all cold starts are equal. There are varying temperatures and the lubricant you need will depend on the ambient temperature. If temperatures are below -20 C/- 4 F, it is recommended to use base oils that can flow in low temperatures. For engine oils, using an SAE 0W or SAW 5W grade lubricant is recommended. When the temperature drops below -30 C/- 22 F, operators should use a SAE 0W or SAE 5W lubricant, but whose base oil is a synthetic base stock and/or a base oil that is considered “multi-grade” or “multi-viscosity.”

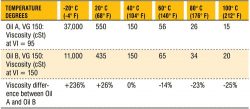

Many of these multi-viscosity and multi-grade lubricants are designed for extreme weather conditions including cold start conditions. These lubricants maintain their viscosity better than conventional lubricants. Generally, multi-viscosity lubricants exhibit viscosity characteristics found in 2 different ISO viscosity grades (i.e. ISO 32-46) and multi-grade lubricants exhibit viscosity characteristics found in 3 different ISO viscosity grades (i.e. ISO 32-46-68).

Viscosity Index

When the temperature drops, the lubricant becomes more viscous, thus making it more difficult to circulate and flow through the engine or machine. Having a lubricant with a high viscosity index, defined as a viscosity index greater than 130, ensures that your lubricant better maintains its viscosity in extreme temperatures. Lubricants with high viscosity indices have either a highly refined or synthetic base stock or include viscosity index improver additives.

Monograde lubricants will have viscosity indices in the 95-105 range and will not perform as well as in cold start conditions. Many operators will use different monograde lubricants depending on the ambient temperature. This may cause issues with change outs and cold temperature properties.

Pour Point

As mentioned earlier, not all cold starts are created equal. In colder temperatures, a lubricant’s pour point could be the difference between success and failure. Pour point is defined as when a lubricant no longer flows and congeals. When operating in temperatures below -30 C/-22 F, it is imperative to use a lubricant with a pour point lower than -50 C/-58 F. Similar to viscosity index, lubricants with highly refined or synthetic base stocks have lower pour points. Some lubricants are manufactured with pour point depressants that prevent wax formation and the congealing of the lubricant.

Oil Integrity and Storage

While you can meticulously select the perfect lubricant based on your OEM requirements, ambient climate, and budget, it could be costly if you do not maintain it properly. Just like any oil, it is important to regularly check the oil for cleanliness and contamination. Taking regular samples is key to ensure your lubricant and machine is in good health. When storing lubricants. It is helpful to store the lubricant indoors or in a warmer environment so that it flows easily during start-up. Proper storage will also protect against contamination. If contaminated, the additives such as VI improvers or pour point depressants may not be as effective and could hurt lubricant performance.