While researching lubricants, there are many factors to consider in selecting a lubricant: viscosity, flash point, pour point, and oxidation stability. Viscosity is the most important parameter since the viscosity grade can be the difference between optimal performance and machine breakdown. However, the ISO Viscosity Grade (VG) is determined at 40⁰C and will fluctuate depending on operating temperature. Viscosity index is a measure of how much the viscosity will change as temperature rises or falls.

Viscosity Index Explained

Viscosity requirements are based on things such as: component design, loads, and speed. Machine recommendations do not account for operating temperatures and temperature ranges. Therefore, it is imperative to take into account average operating temperature when selecting a viscosity. To account for changing temperatures, the viscosity index was developed to measure viscosity stability as temperatures change. Viscosity index is a unit-less number that is derived by measuring a fluid’s viscosity from 40⁰C to 100⁰C.

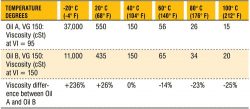

The higher the viscosity index, the greater the stability of the lubricants viscosity. As shown in the chart below, the difference in viscosity index could greatly affect lubricant viscosity and performance:

As temperatures move towards extreme highs and lows, the difference in Oil A and Oil B is magnified. Oil B, which has a VI of 150, maintains a viscosity closer to its ISO VG of 150 as temperatures rise and fall. On the other hand, Oil A fluctuates much more and could adversely affect performance at extreme temperatures. If your operation will have fluctuating loads, speeds, temperatures, etc., it is imperative to select a lubricant with a higher viscosity index.

Viscosity indexes, which can be found on most product data sheets, typically range from 90 to 160, but can exceed 400 and be as low as -60. The viscosity index can also give insight into the type of base oil and its quality. More refined mineral oils and synthetics will have higher VIs than lower quality base oils. Some products may include viscosity-index improver additives to help stabilize the lubricant in extreme conditions. VI-improver additive molecules adopt a coil shape in cold temperatures and have little effect on viscosity. In higher temperatures, the molecules uncoil and thicken the oil to stabilize viscosity. However, it is important to note that oils with VI-improvers will see permanent loss of VI and viscosity over time.

When Should You Opt for Higher VI

If your operations are going to have variable loads, variable temperatures, variable speeds, and other environmental variables, it is important to select a lubricant with a higher viscosity index. As these variables change, so will the lubricants viscosity. Therefore, it is crucial to invest in a lubricant that will maintain an optimal viscosity across different operating conditions. Conversely, if your operation is fairly consistent, it may suit you to select a lubricant with a lower viscosity index in order to save money.

Some machines may not possess data to identify the optimum viscosity, which could be problematic as ISO viscosity grades are separated by 50% increments between grades (e.g. 46 → 68, 100 → 150). With such large increments, finding the precise optimal viscosity becomes even more difficult. This problem is magnified at lower temperatures, where differences in lubricant viscosity are much larger (as shown in the chart above).

Calculating VI

If you are unsure of a lubricants viscosity or viscosity index, there are online calculators available to help you. If you are unsure of a viscosity index, simply enter the viscosity at two different temperatures and it will return the viscosity index. If you are unsure of a viscosity at a given temperature, enter a known viscosity, known temperature and viscosity index to find the desired temperature to find the new viscosity.

Key Takeaways

In conclusion some of the key reasons to have a lubricant with a higher viscosity index include:

- Optimal operating viscosity is unknown

- Varying operating temperatures and/or extreme operating temperatures

- Other operating variables such as speed and load

- You want to increase energy efficiency

- You want to extend oil service and machine service life

Most of these involve improving performance that may be adversely affected by operating uncertainties. In these instances, it is ideal to opt for lubricants with higher VI. In the following instances, using cost-effective lower VI lubricants may prove beneficial to your bottom line:

- Constant speeds and loads

- Operating temperature remains the same

- Optimal viscosity is known and can be consistently reached

If there is more certainty with your operating process, it may not be necessary to invest in a lubricant with a higher VI. It is important to evaluate your operating processes and consult machine manuals to understand your operating conditions. If you are faced with uncertainty and variance in your operations, a higher viscosity index will help smooth operations and increase performance across different loads, speeds, and temperatures.