Used for over 3000 years, grease is a key lubricant used to operate a variety of machines and bearings. Over 80% of the world’s bearings are lubricated with grease. Grease is an excellent lubricant to use when liquid lubricants fail to do the job. Greases are made of three main components: base oil (70-95%), thickener (3-30%), and additives (up to 10%). We are going to examine the second component: thickeners. Thickeners are essential as they are the “sponge” that holds the base oil and additives.

What are Thickeners?

When combined with the base oil and additives, the thickener forms a semi-fluid structure. Conventional thinking suggests the structure indicates the grease is mainly thickener, however, the thickener is a material that holds the lubricant until it is dispersed. As mentioned above, the overwhelming majority of any grease is composed of base oil. There are many types of compounds that can be used as thickeners.

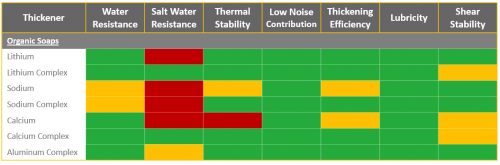

Greases are classified into two major families: soap and non-soap thickeners. Over 90% of greases worldwide are classified as soap thickeners. Soap-based thickeners are produced via an acid-base reaction known as saponification. The end-result is a soap and water mixture. The water is removed and the remaining soap is used as a thickener for grease. The type of soap thickener will depend on which acids and bases are used in saponification. Some common compounds used are:

- High molecular weight fatty acids: Stearic and 12 Hydroxy Stearic Acid (12 HSA)

- Short chain complexing acids: Tallow, Azelaic, and Sebacic Acid

- Most bases are a metallic hydroxide compound (i.e. lithium, calcium, etc.).

Types of Soap Thickeners

Simple Soap: This results from the reaction of one fatty acid and a metallic hydroxide. The most common soap, lithium soap, is produced

with 12 HSA and lithium hydroxide. The metallic hydroxide defines the thickener and other types besides lithium can be used.

Mixed Soap: Less common than simple soap, mixed soap is created in similar fashion as simple soap. However, the “mixed” characteristic is derived from mixing multiple metallic hydroxide compounds with a fatty acid. A common mixed soap is Ca/Li soap, which is made with calcium hydroxide and lithium hydroxide.

Complex Soap: Like simple soaps, complex soaps use a single metallic hydroxide. In order to create the complex-thickened grease, a fatty acid is combined with a short chain complexing acid. The acid mixture is then combined with a metallic hydroxide to for a complex thickener. Lithium complex grease, the most popular in North America, is made with lithium hydroxide, 12 HSA, and azelaic acid. These thickener types have an advantage over simple soap because of better high-temperature properties.

Types of Non-Soap Thickeners

Urea: Also known as polyurea, these thickeners are a reaction product of di-isocyanate combined with mono and/or diamines. The ratios of the ingredients will determine the characteristics of the thickener. This classification includes diurea, tetraurea, urea-urethane and others. Since there are no metallic elements in polyurea grease, the grease is ashless and subsequently more oxidatively stable. Polyurea greases are the most popular non-soap grease today.

Organophilic Clay: Also referred to as organo clay or clay thickeners, these thickeners are mineral based usually made from bentonite, hectorite, or montmorillonite. The minerals are purified into a clay and treated to be compatible with organic chemicals. The clay is dispersed in a lubricant to form a grease. Clay greases have no melting point and are traditionally used in high-temperate greases (however the oil will oxidize quickly at elevated temperatures).

Other: Polyurea and clay thickeners are the most used non-soap greases, but there are some other specialty thickeners that are used. These include:

- Teflon

- Mica and silica gel

- Calcium sulfonate

- Polytetrafluoroethylene (PTFE)

- Carbon blacks

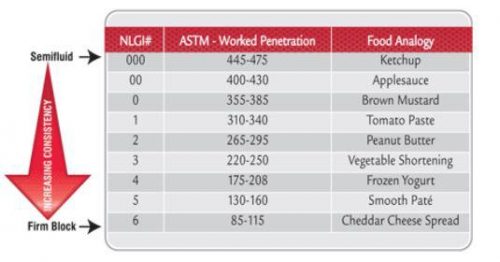

NLGI Classifications

In addition to composition, the other key classification for grease is quite obvious: thickness. Defined as consistency, a grease’s consistency is its resistance to deformation by applied force. This is measured by penetration. A standard test, specifically ASTM D217, measures cone penetration after five (5) seconds for a grease at 77 F (25 C). The unit of measure is tenths of a millimeter and the NLGI classifies grease based on its penetration. The range of grades is 000 to 6. See the chart to the left for a full breakdown NLGI grades.

Most greases today fall in between the 1 and 3 grades with NLGI 2 being the most common. High penetration greases such as 00 and 0 can be used in central systems and colder environments.

Selecting the Appropriate Thickener and Grade

The right grease could vary greatly depending on your application, operating environment, and other factors. High temperature environments may require firmer (higher NLGI grade) greases and certain thickeners with high-temperature properties. It is best to consult OEM guides or speak with your grease manufacturer or distributor to get a recommendation.

Switching and mixing greases could either prove to be extremely costly. Most thickeners do not mix together and there are specific greases that are not compatible with others. It is recommended to match “like-for-like.” If you plan to make a switch, it is best to completely drain your equipment before applying new grease.