Written by Peter Jacobs, CNC Masters

During machining operations, overheating can have detrimental effects on the workpiece and the equipment, which could be avoided by cooling them down post-usage. Therefore, cooling is crucial for most machines to function efficiently and effectively.

Hence, this article covers a wide range of aspects related to the usage of coolants in CNC machining, including their purpose, the many kinds of coolants utilized, and their characteristics. Let’s delve deeper.

What’s the Significance of Coolants in CNC Machining Operations?

While executing a milling or turning operation using a desktop CNC mill, the heat gets produced as a byproduct of the materials being sheared off the workpiece and by the friction of the chip moving across the cutting tool. Rapid tool wear occurs at high temperatures, and undesired changes in the workpiece’s metallurgical properties and toughness, thermal expansion, and chemical reactions like oxidation can only materialize at high workpiece temperatures. Since this is the case, you should employ a coolant to maintain a steady temperature between the workpiece and the tool.

Vital properties of coolants include-

- Enhanced lubrication and cooling performance,

- The surface of the workpiece gets protected from corrosion,

- They aid in maintaining chemical, physical, and technical stability,

- They prevent excessive forming.

The primary purpose of coolants is-

- Cooling- While in the case of very mild cuts and moderate duty cycles, air may also be employed as a coolant. However, this time-consuming and labor-intensive cutting process occurs during production. Therefore, liquid coolant is used to quickly evacuate heat from the tool, which aids in speed cutting and reducing friction and tool wear, making it possible to maintain a steady production stream.

- Lubrication- Cutting fluid is not only utilized for cooling but also as a lubricant between the workpiece and the tool’s cutting edge. The heat created during machining can cause chips to weld themselves to the tool if they aren’t lubricated first.

Common Types of Coolants

There are four primary classifications for coolants, and within each of those, there is a wide range of possible compositions. When choosing a coolant, you should base your decision on the comprehensive performance & efficiency it offers concerning the machining operation and the materials being utilized.

- Soluble Oils: The most prevalent type of water-soluble cutting fluids, soluble oils, are also an excellent alternative for general-purpose machining because of their versatility. The disadvantage of these systems is that when the coolant sump is not well treated, they are more likely to experience the microbial proliferation of bacteria and fungi.

- Synthetic Fluids: These are the cleanest cutting fluids as they do not include any mineral oil and repel tramp oil. Additionally, synthetic coolants offer the least amount of lubrication.

- Semi-Synthetic Fluids: They are regarded to provide the best combination because they contain fewer oils than emulsion-based fluids, have a less putrid odor, and, nevertheless, retain most of the lubricating properties of emulsion-based fluids. Given all such features, they are suitable for a greater variety of machining applications.

- Straight Oils: Straight oils are distinguished from other types of oils as they are insoluble in water; they are made up of a mineral or petroleum oil base and include lubricants such as fats, vegetable oils, and esters. They have the best lubricating properties but the worst cooling properties.

How Do Coolants Get Delivered to CNC Machines?

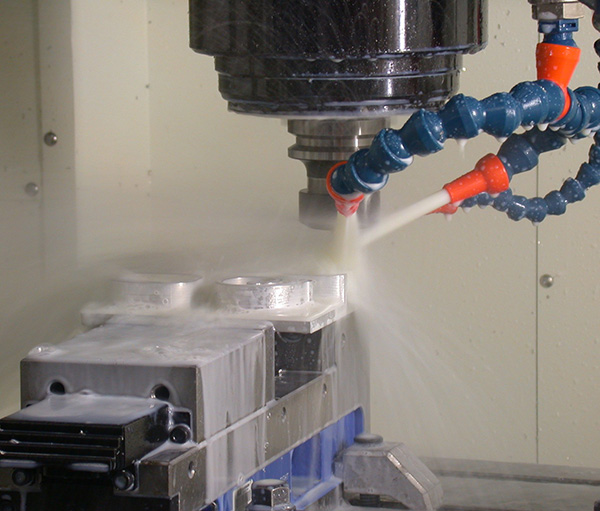

Cutting fluids can be applied in various ways; the most effective method will vary depending on the operation at hand and the equipment at disposal. Coolant is typically supplied at high pressure and volume straight to the chip-tool contact in a metal cutting process, with valves surrounding the machine to confine the splash and others to reach the filter and recirculate the fluid. The probability of flooding is reducing as technology improves. The novel method incorporates a variety of liquids, aerosols, and gas delivery options. One technique is to use cryogenic cooling on the tip of the tool to lubricate it with a minimal amount of oil.

A through-spindle coolant system uses the spindle and the tool themselves as channels to transport coolant to the cutting interface. Nowadays, high-pressure coolant systems are also used.

Importance of Maintaining Appropriate Coolant Concentrations

Many problems might arise if coolant concentrations are not kept at the right amounts. There’s a significant risk if the coolant concentration is lower than the minimum ratio required by the machine coolant supplier, which may include:

- Corrosion of machinery and workpiece

- Tools wear out faster

- Microbial growth

However, if the coolant concentration is excessive, the following will occur:

- Lowering of heat conduction

- Foaming

- Weakened lubrication

- Concentrated wastage

- Degradation of tools owing to residue buildup

- Discoloration of machinery and machined components

Therefore, it is essential to keep a log sheet of concentration levels for every CNC equipment since this provides insight into the system operation and the degree to which concentration levels fluctuate daily.

Conclusion

Learning about the various types of coolants and how they function will help you choose one that is ideal for your equipment and machining operation. Also, the life of your tools and machinery, as well as the coolant itself, can be dramatically increased with regular monitoring of coolant concentration. Twin Specialties has been supplying metalworking fluids since 1955. We have years of expertise to assist you in selecting the right fluids for your machining needs.

About the Author:

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights to various blogs on CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.

Twin Specialties is an authorized distributor for Monroe Fluid coolants, oils, rust preventatives, and industrial cleaners. Contact Twin Specialties to learn more about Monroe Fluid’s product line and learn about our sampling and testing programs. Check out Twin Specialties’ catalog of

Twin Specialties is an authorized distributor for Monroe Fluid coolants, oils, rust preventatives, and industrial cleaners. Contact Twin Specialties to learn more about Monroe Fluid’s product line and learn about our sampling and testing programs. Check out Twin Specialties’ catalog of