This is a copy of the post created by Monroe Fluid Technology, June 2021. Used with permission.

Written by Fred Kane, Monroe Fluid Technology

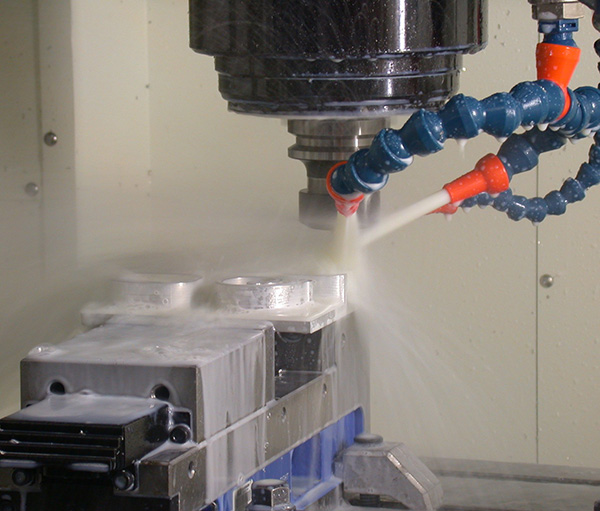

Monroe Fluid Technology has two ‘workhorse’ water soluble oil concentrates, designed specifically for the demands of heavy duty machining applications. Where a chlorinated additive is specified, our Astro- Sol C HD is recommended. In circumstances where a chlorinated additive may not be suitable, we offer Astro-Sol A-XBP. Both are low foaming products, suitable for virtually all metals and applications, and are designed to resist bio-degradation.

Astro-Sol A-XBP

Astro-Sol A-XBP is a medium-to-heavy duty biostatic soluble oil. This product was designed to be extended with water for the machining and grinding of virtually all metals except magnesium. This chlorine-free formulation is especially suited for aerospace and other applications which restrict the use of chlorine. Astro-Sol A-XBP has exceptional foam control for high-pressure operations and was designed using raw materials that have the ability to resist extreme biological degradation, thus providing a very long sump life in a properly maintained machine tool. Astro-Sol A-XBP is designed for use in metalworking applications such as all CNC milling, turning, drilling, tapping, grinding and sawing applications.

Astro-Sol C HD

Astro-Sol C HD is an extreme duty soluble oil concentrate designed for the most demanding machining operations where controlled foam and cleanliness are required. The unique combination of chlorinated extreme pressure additive, modern boundary lubricants, and a controlled-foam emulsifier package brings outstanding performance to the most severe applications. Astro-Sol C HD is formulated with a high level of stabilized chlorinated EP additive using a synthetic emulsification platform that is very stable and exceptionally low foaming. Astro-Sol C HD is designed for use in heavy-duty metal removal, deep hole drilling, tapping and threading, as well as all conventional machining and is very effective in sawing operations.

Trial Monroe Metalworking Fluids

If you have an interest in trialing one or both of these products, just inquire and we will send samples and also our Astro-Clean A, a sump cleaner you can add directly on top of your current coolant, run for 24-48 hours while making parts, then dump, rinse and recharge with the new coolant. Remember, water quality is important, so we may need a sample of your water for testing, or if you know the hardness of your water, we can resolve that issue easily.

Twin Specialties is an authorized distributor for Monroe Fluid coolants, oils, rust preventatives, and industrial cleaners. Contact Twin Specialties to learn more about Monroe Fluid’s product line and learn about our sampling and testing programs. Check out Twin Specialties’ catalog of metalworking fluids, rust preventatives, and industrial cleaners.

Twin Specialties is an authorized distributor for Monroe Fluid coolants, oils, rust preventatives, and industrial cleaners. Contact Twin Specialties to learn more about Monroe Fluid’s product line and learn about our sampling and testing programs. Check out Twin Specialties’ catalog of metalworking fluids, rust preventatives, and industrial cleaners.