Finding the optimal metalworking fluid is a difficult task because no fluid is “one-size-fits-all.” Each shop has its own unique set up of machines, operations, metals, etc. Operators have to consider many factors before selecting the optimal fluids or fluids for their shop. The optimal fluids should successfully perform the following core functions:

- Lubricate the cutting edge

- Disperse heat from the cutting edge and workpiece

- Flush away chips from the cutting edge

Additionally, there are secondary functions a coolant can improve your operations. These include:

- Corrosion protection

- Extending tool life

- Reducing energy consumption and machining forces

- Improve surface finishing

To find a coolant that can perform these functions, you should take the following factors into consideration.

Machine Requirements

The types of machines in your shop will determine what type of fluid you will need. Older, swiss-type lathes can use neat oils. Whereas newer and more sophisticated CNC mills and lathes perform better with a water-soluble product. This is because higher speeds and higher pressures need more cooling than swiss-type lathes. The water does an excellent job cooling the cutting edge and workpiece. For neat oils, the cutting diameter plays a key role in determining the appropriate viscosity. The smaller the diameter, the lighter the viscosity should be to maintain and improve flow characteristics.

If your machine is operating at high speeds and/or high pressures, it is wise to consider a low-foam coolant or a specialized “high-pressure” coolant to use. Synthetic coolants are also an option as they tend to have lower foam rates than semi-synthetic and soluble oils. If your shop has a wide variety of machines and operations, you can consider using different fluids that are tailored to each operation. Over-consolidation can cause issues and may not be worth the savings. Fluids can be bought in smaller quantities and be used in limited cases to ensure performance and tolerances are met.

Shop Preferences

Machines do the heavy-lifting in metalworking, but there are still people behind each operation programming the CNC or working the lathe. Operators always get coolant spray on their skin and could be subjected to mist or spray. Finding a product that does not cause irritation nor spray/mist is paramount to keeping your operators safe and happy.

Shops have to consider the costs and labor involved in changing fluids as well as maintaining fluids. Cheaper fluids may save money, but will require more maintenance, monitoring, and change-outs. If your time is limited, investing in higher cost fluids will free up time to complete other machining tasks.

The ancillary equipment in the shop also can influence what type of fluid you need. If your sumps are equipped with oil skimmers, paying extra for a fluid with advanced tramp-oil-rejection characteristics may be unnecessary. Automatic mixers makes synthetic coolants a more attractive option since the concentration control required for synthetics is much more stringent than semi-synthetics and soluble oils. Understanding what is in your shop will help determine what fluid is appropriate for you.

Operations and Water Quality

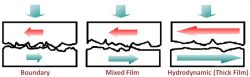

As mentioned before, operations with higher speeds and pressures will call for a fluid with robust extreme-pressure (EP) additives to cut the toughest metals. In slower operations, a soluble or neat oil can be sufficient.

Your shop’s location will play a key role and fluid selection since the tap water is different in each town. If your shop has harder tap water, your machining might be negatively affected with higher chloride and sulfur content. Softer water is susceptible to more foaming. Avoid using softer water in higher pressure machining to limit foaming issues. It is recommended to charge up a sump with tap water and then use deionized (DI) water for topping off the sump and maintenance.

Shops can install a DI-Water line that can hook right up to an automatic mixer and improve coolant mixing. Distributors, like Twin Specialties, offer water testing services in the context of metalworking fluids. We can learn more about your water and make product and operational recommendations to improve coolant performance.

Workpiece Materials

Not all metals are the same. Some are soft, some are hard. Some metals are more reactive and require more care and specialized fluids. Magnesium requires certain additives or fluids that designed to machine magnesium. When machining carbide, it is best to use an amine-free coolant that does not react with the carbide and result in cobalt leaching. Harder metals like Inconel or titanium require coolants with EP additives and superior cooling to ensure heat is dispersed and friction is reduced. If you machine titanium or exotic metals in limited circumstances, it may be beneficial to keep a pail or a few gallons of a robust coolant in storage used specifically for those jobs and operations.

Potential Contamination

Contamination can occur frequently and in many forms. The main contaminants to watch for are: oxidation, tramp oil, and biologics. To combat oxidation, many fluids have anti-oxidant additives. It is key to monitor temperature as excessive heat will oxidize the oil. Antioxidants are limited in coolants; once all of the additive is consumed, the oil degrades quickly and will need be replaced sooner rather than later.

Tramp oils can change the oil’s viscosity, thus its flow characteristics. Having coolants with tramp-oil-rejecting compounds will help, but using oil skimmers is an excellent option to combat tramp oil. The skimmers remove the oil off the top of the sump and limits tramp oil being circulated through the machine. Oil filters are recommended to keep tramp oil from circulating through the system. Neat oil systems should use 5 micron filters and coolant systems should use 15 micron filters.

Outside biological contamination like bacteria can wreak havoc on your machine and cause clogs and ruin your fluid. Many fluids contain biocide additives to combat bacteria, but many factors allow it to grow uncontrolled. Be mindful to thoroughly clean your machine before recharging it. Any remnants of bacteria will multiply and ruin your fluid. Hot operating environments spur bacteria growth so it is recommended to implement as much climate-control in your shop as possible. Circulating the coolant will also make it tougher for bacteria to grow. Tank-side biocide additives like Grotan can supplement fluids and fight bacteria. Ensuring your coolant has proper concentration will ensure there is enough biocide to prevent bacteria growth.

Concentration

Monitoring concentration is key for maintaining your fluid. Some fluids, like synthetics, require tighter control and more monitoring. If you are limited by time, using a soluble or neat oil will reduce the time needed to monitor your fluid. Coolants typically run between 5 to 15% concentration. Using a refractometer to regularly track concentration is the best way to monitor and maintain coolants. Technical data sheets include refractometer charts and BRIX factor information to ensure the coolant is mixed optimally. If the line in the refractometer is blurry, that is a sign of contamination in the sump. Automatic mixers are ideal for charging sumps and eliminate human error or measuring biases that may occur when mixing coolant.

Takeaways

Selecting a metalworking fluid is a thorough and long process. Taking these considerations into account will set you up for long-term stability and success. Working with a metalworking fluid distributor and/or manufacturer is strongly recommended to help select to correct product. Twin Specialties offers a wide range of metalworking fluids and fluid maintenance resources to ensure you get the most out of your fluid.