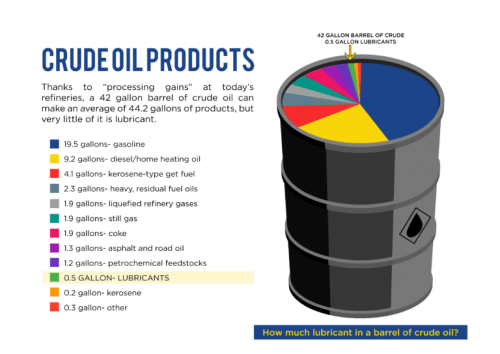

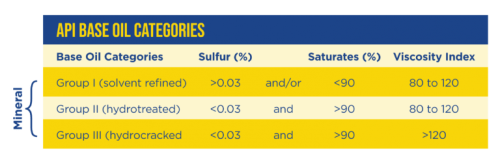

In any oil-based lubricant the base oil will compose 80-99% of the product you use. What are differences in the main ingredient of your lubricant? The American Petroleum Institute classifies base oils into 5 groups. These classifications are based on the chemical composition of the base oil and the treatment of the base oil.

If a base oil is classified as Group I-III, that base oil will be composed of crude oil that has been treated. The differences depend on the treatment processes applied to the oil.

Petroleum Base Oils

Group I

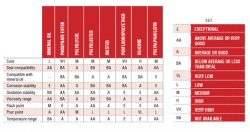

Group I base oils are the least refined base oil. Two main characteristics of Group I base oils are that they are composed of less than 90% saturates and/or greater than 0.03% sulfur. If either of these conditions are satisfied, then the base oil will be classified as Group I. The only process that is used is solvent refining, which allows Group I base oil products to be cheaper than their more refined equivalents. These are generally used for less-demanding applications and could be ideal for applications where lubricant consumption is high.

Group II

Group II base oils are more refined than Group I. In addition to solvent refining, these oils are also hydrocracked purify the oil. Unlike Group I base oils, these base oils must contain over 90% saturates and less than 0.03%. The greater percentage of saturates gives these lubricants better antioxidation properties than Group I base oils.

Failure to meet either of these requirements will result in a Group I classification. These products also have a viscosity index of 80-120. These oils have good performance in volatility, oxidation stability, wear prevention, and flash point. They only have fair performance in cold temperature environments. Given costs of treatment today, Group II lubricants are most commonly used today and many users have switched from Group I oils to Group II oils.

Unofficially, there is a Group II+ that are composed of high-end Group II base oils. These base oils must have a viscosity index of 110-120 to be considered Group II+.

Group III

Group II base oils must meet the same conditions (saturates and sulfur) as Group II, but also must have a viscosity index greater than 120. These base oils are severely hydrocracked, hydroisomerized, and hydrotreated to crate the best grade of petroleum base oil. These products offer superior stability and molecular uniformity, which makes them ideal for some semi-synthetic lubricants.

Some people consider Group III base oils to be synthetic. The API classifies them as mineral oil since they are derived from crude oil. They do mimic characteristics of synthetic oils including high viscosity indices. A lawsuit between Mobil and Castrol occurred due to Castrol marketing their Syntec lubricant as a synthetic even though it was composed of Group III base oils. In a 1999 ruling, the product was allowed to marketed as a synthetic.

Many people reject the decision and only consider Group IV and Group V base stocks as “synthetic.” Some Group III lubricants outperform Group IV lubricants if they contain excellent anti-wear, anti-oxidant, and other additives. Similar to Group II, Group III base oils have an unofficial Group III+, which consist of Group III oils that have a “Very High Viscosity Index (VHVI).” The VHVI minimum is anywhere between 130-140.

Synthetic Base Oils

Group IV

Group IV base oils are synthetic base oils that composed of polyalphaolefins (PAOs). These products have a viscosity index of 125-200. These base oils are not extracted from crude oil, but made from small uniform molecules. The uniformity and manufacturing of these oils allows for predictable properties that assure performance in tough conditions. These properties include extreme temperature stability, which makes these products ideal for cold and hot weather climates.

Lubricants composed of polyinternalolefins (PIOs) are considered to be in the unofficial Group VI. Similar to PAOs, PIOs use different chemicals in its synthesis process to obtain an even higher viscosity index. Their official API classification would be Group V. Certain food grade lubricants are composed of Group IV PAOs.

Group V

Group V base oils are any base oil that is not classified as a Group I-IV base oil. Common Group V base oils are polyalkylene glycols (PAGs) and various esters. One exception is white oil, which is a very pure lubricant commonly used in cosmetics and food processing. Also used in food grade lubricants, Group V base oils such as PAGs or esters can be used in certain biodegradable base stocks rather than vegetable or seed oils. It is important to note that most PAGs are only compatible with other PAGs.

Key Takeaways

When selecting a lubricant, it is important to understand what base oil is used. Given that the base oil is 80-99% of a lubricant, you should know what base oil you are using. Upgrading the Group III or Group IV could improve performance and reduce consumption. Twin Specialties offers a variety of industrial and specialty lubricants made from a variety of base stocks to meet your operating and budgetary requirements.